Engineering student invents, markets equipment solution

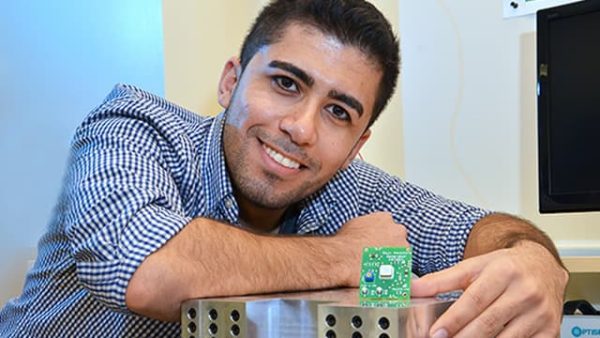

Needing multiple units of an expensive piece of equipment to complete his doctoral project, mechanical engineering student Sajad Kafashi decided to invent and build his own. Now, in addition to finishing his Ph.D., he is commercializing his invention, which he calls the Saji Waveform Generator.

Kafashi is working on a Center for Precision Metrology doctoral project titled “Contact Free Microparticle Manipulation.” The goal of this research is to design and build a dynamic particle imaging system for particle trajectory tracking studies in millimeter to micrometer scale flows. The project involves analyzing the dynamics of how microparticles (ranging in size from 10 to 150 micrometers in diameter) move and behave in water while oscillating actuators are induced into the solution.

“The project requires a lot of image processing to analyze how the particles move and change,” Kafashi said. “We record the movement with a camera and then process the images in MATLAB.”

The rods that create the movement are controlled by waveform generators that produce periodic electrical waveforms. The resulting waveforms can be injected into a test device and analyzed as they progress through it. Traditional waveform generators are expensive and cumbersome to use with manual knobs that have to be turned and adjusted.

“My advisor, Dr. Stuart Smith, and I said ‘Why not make our own waveform generators?’” Kafashi said. “So, we created the Saji Waveform Generator, which is a compact, computer-controlled and inexpensive electrical waveform generator.”

In the development of the product they were helped by UNC Charlotte’s entrepreneurial services organization Ventureprise and a $3,000 grant from the National Science Foundation’s Innovation Corps Teams Program. They developed several versions of their waveform generator, making it increasingly efficient, inexpensive and compact.

Because the Saji Waveform Generator is much smaller than current waveform generators, Kafashi said, “It can be built into other pieces of equipment and then controlled through software with a computer. This eliminates turning knobs and dials and allows users to select frequency, amplitude and other parameters on their computer and then simply hit send and adjustments are made in real-time. We spent about a year programming the chip to get it perfect.”

Most electrical laboratories in schools have more than 10 waveform generators, costing an average of $3,000 to $4,000 each. Kafashi plans to sell his for less than $200. He currently has about 100 made and is now working on plans to market them. “We are finalizing our product discovery phase and our strategies for commercialization,” he said.

The Saji Waveform Generators already have been used in other projects in the Center for Precision Metrology, including the development of micro-robotics and a synchronized phase extraction interferometry project. They will also be used in experiments in the Advanced Instrumentation Lab course being taught to undergraduate students. Innovate Carolinas has awarded the product a certificate of achievement as one of the top three innovative ideas in the Carolinas in 2015.

In terms of his future when he graduates, Kafashi said designing and building his own invention has been inspiring. “I would like to do product development and research in R&D for industry,” he said. “Then someday I’d love to have my own company developing products.”